NEWS

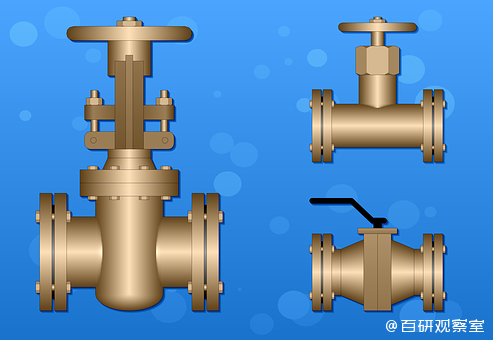

What kinds of lead, brass, copper

Lead brass is a yellow alloy with copper, lead and zinc as its main components, its bright color,

high ductility and strength, and excellent corrosion resistance at the same time, these unique

characteristics make it an ideal material for a variety of manufacturing fields.

Leaded brass is a leaded brass alloy consisting mainly of copper (Cu) and lead (Pb), but also

containing small amounts of zinc (Zn) and other elements.

Chemical composition of lead brass

What kinds of lead, brass, copper

1, copper (Cu) : 59.0% ~ 63.0%

2, lead (Pb) : 0.8% ~ 2.5%

3, zinc (Zn) : margin

4. Other elements: < 0.5%

Lead brass alloy characteristics

Lead brass has good toughness, corrosion resistance, workability and thermal conductivity, and

has good cutting edge and lubrication.

Physical properties of lead brass

1, melting temperature range 886 ~ 901℃

2, thermal conductivity A=104.7W/ (m·℃)

3, specific heat capacity c=377J/ (kg·℃).

4. Density p=8.50g/cm³

5, electrical conductivity g=27%IACS

6, resistivity p=0.065μl m.

7, when the magnetic field strength H=700kA/m, room temperature mass susceptibility

X=-0.09×10~'m3/kg.

Lead brass, what are the types of copper? What are the types of lead brassChemical properties

of lead brass

The high temperature oxidation resistance of the alloy is poor, and the surface of the oxidation

is not dense oxide film, the inner layer is ZnO, the outer layer is Cu2O, and the phenomenon of

dezincification is associated with the oxidation.

Corrosion resistance The alloy has good corrosion resistance in the atmosphere, fresh water and

organic solution, but has a

greater tendency to stress corrosion failure in the cold hardening state.

What kinds of copper are there

What kinds of lead, brass, copper

1, copper: refers to pure copper, the density is 8.96, the melting point is 1083℃. It has good

electrical conductivity, thermal

conductivity, especially excellent plasticity, and is used in large quantities for wires, cables, brushes

and other conductive products with high conductivity requirements. In order to improve the material

and performance, a small amount of deoxidation elements and other elements are added, so it can

also be classified as copper alloy. Copper is also widely used in chemical industry, conductive, thermal

equipment, can also be processed into a variety of semi-finished products, finished products. Mainly

oxygen-free copper, silver copper, phosphorus deoxidized copper, copper;

2, brass: refers to zinc copper alloy, can also be divided into ordinary brass and special brass. Ordinary

brass with 39% zinc content as the dividing line, less than 39%, plasticity is good, usually suitable for

hot and cold pressure processing. Greater than 39%, suitable for hot pressing. Special brass refers to

the common brass to add metal, iron, zinc and other alloys composed of multiple alloys. Adding

alloying elements can increase the tensile strength. Among the elements, the third group of complex

brass is named silicon brass and nickel brass; The color changes from yellowish red to light yellow

with the increase of zinc content.

3, bronze: refers to the copper base alloy except copper nickel, zinc copper alloy, mainly tin bronze,

aluminum bronze, special bronze, special bronze is also known as high copper. Tin bronze is suitable

for making bearings and gears. Lead bronze is suitable for the manufacture of modern engine and

grinder bearings. Aluminum bronze is suitable for manufacturing high load gear, Marine propeller

and so on.

4, white copper: refers to copper-nickel alloy, the content of nickel in white copper is 25%. The color

is silvery white and glossy. Nickel content is positively correlated with white color. The mechanical

properties and physical properties of white copper are higher than those of other copper alloys.

At the same time, the ductility and hardness of white copper are excellent, and it is widely used in

electrical appliances, meters, medical equipment and other aspects. White copper also has drawbacks,

that is, the nickel component in white copper is not common, and the price is also expensive.

5, natural copper: steel content is higher than 99%, but the reserves are very small. The whole is

copper red, high density and strong ductility. At the same time, natural copper also has the properties

of traditional Chinese medicine, and is used in promoting blood circulation and removing blood stasis

and analgesic drugs.

6, copper oxide: the number is not large, the more common is malachite and azurite, followed by

silicon malachite and copper.

7, copper sulfide: copper content of 2%-3%, the world's copper refined from sulfide copper is higher

than 80%. It is brown and very insoluble.

8. Copper concentrate: ores with higher copper content selected before smelting

9, crude copper: copper concentrate after smelting to obtain crude copper, copper content of

95%-98%

Source: Mechanical design, Shanghai Hankai Metal, recycling little angel

Note: All pictures in the article are network reprint pictures, infringement is deleted!

The original link: https://www.xianjichina.com/news/details_308182.html

Source: Xianji network

The copyright belongs to the author. For commercial reprinting, please contact the author for authorization.

For non-commercial reprinting, please indicate the source.